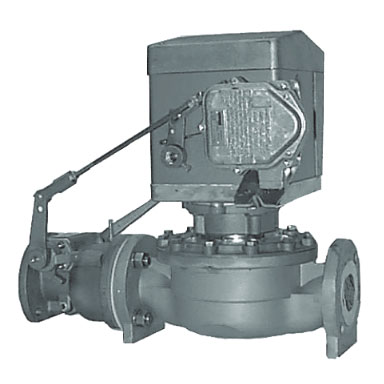

Neptune Model 23 Auto-Stop Switches, used with 800 series preset registers, extend the Auto-Stop feature to electrically operated systems for the remote actuation of valves, pumps or other accessory equipment. They can be supplied on new flowmeters or added to flowmeters already designed for Auto-Stop operation. They can be used with any 800 Series Preset Register.

Neptune Model 23 Auto-Stop Switches, used with 800 series preset registers, extend the Auto-Stop feature to electrically operated systems for the remote actuation of valves, pumps or other accessory equipment. They can be supplied on new flowmeters or added to flowmeters already designed for Auto-Stop operation. They can be used with any 800 Series Preset Register.

There are two types of Auto-Stop Switches, 23A and 23B. They are identical in outward appearance; however, the Model 23A is a two-stage switch used with actuated valves and the Model 23B is a single stage switch.

Model 23A

The Model 23A is designed to be used only with a double-trip Auto-Stop Register. The Model 23A provides two switch closures for two-stage shutdown of solenoid valves with the final closure also de-energizing the pump if needed. No mechanical valve is needed with the Model 23A switch. Model 23A switches are double-pole double-throw (DPDT).

Model 23B

The Model 23 B can be used with either a single trip or double trip Auto-Stop Register. Model 23B Switches provide one switch closure for single trip valve shutdown and/or pump de-energizing. They may be used with or without an auto-stop valve. Model 23B switches fit to the rear housing of the auto-stop register and allow the operator to electrically energize and de-energize some other device in sequence with the auto-stop register. The Model 23B switch is commonly wired to a motor starter for a pump. When activating the mechanical batch operation at the auto-stop register, the pump is energized at the same time. The switch closes and the pump is de-energized at the end of the batch. The Model 23B switch may be used with the auto-stop register even if a mechanical valve is not used. In these cases, the Model 23B starts and stops the flow for approximate batching application. Model 23B switches are single-pole double-throw (SPDT).

The BATCHMATE may be thought of as two separate counters and a rate meter. The “batching” counter counts to “pre-warn” and “preset” set points entered by the user and enables separate control outputs. The “totalizing” counter gives a cumulative reading or grand total.

The BATCHMATE may be thought of as two separate counters and a rate meter. The “batching” counter counts to “pre-warn” and “preset” set points entered by the user and enables separate control outputs. The “totalizing” counter gives a cumulative reading or grand total.

The Neptune Pulsmate Electronic Register enhances the flow management capabilities of Type MP and magnetic drive Type S flowmeters. This battery or externally powered register displays rate and total simultaneously and includes a scalable pulse output for interfacing with supervisory control.

The Neptune Pulsmate Electronic Register enhances the flow management capabilities of Type MP and magnetic drive Type S flowmeters. This battery or externally powered register displays rate and total simultaneously and includes a scalable pulse output for interfacing with supervisory control.

The Model 157 Register is a non-resettable totalizer that provides an increasing cumulative reading. An input shaft connected to the register change gear drives the register. There is a 1:1 ratio between the input shaft and the first wheel. To measure in increments of more than a single unit, the Model 157 uses “fixed zeros” to the right of the first wheel. A Model 157 Register reading in gallons or pounds is a function of the flowmeter’s gear train ratio and the ratio of the two change gears. For each complete revolution of the pointer, the right hand wheel on the totalizer will rotate one complete revolution.

The Model 157 Register is a non-resettable totalizer that provides an increasing cumulative reading. An input shaft connected to the register change gear drives the register. There is a 1:1 ratio between the input shaft and the first wheel. To measure in increments of more than a single unit, the Model 157 uses “fixed zeros” to the right of the first wheel. A Model 157 Register reading in gallons or pounds is a function of the flowmeter’s gear train ratio and the ratio of the two change gears. For each complete revolution of the pointer, the right hand wheel on the totalizer will rotate one complete revolution.

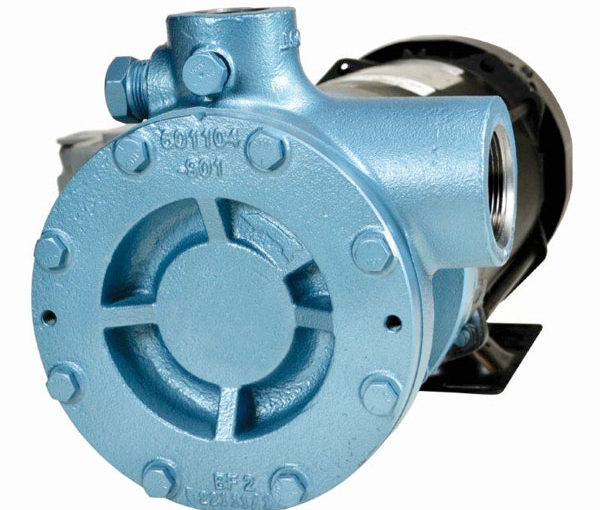

The 600 series Register is mechanically driven designed for easy adaptation to a local or remote batching and recording system. The 600 series register offers a 5 digit delivery quantity reset similar to the Models 831/841 and an 8 digit non-resettable totalizer. It is fully mechanical and does not offer mechanical preset or ticket printing options.

The 600 series Register is mechanically driven designed for easy adaptation to a local or remote batching and recording system. The 600 series register offers a 5 digit delivery quantity reset similar to the Models 831/841 and an 8 digit non-resettable totalizer. It is fully mechanical and does not offer mechanical preset or ticket printing options.

The 800 series register is the latest of four multi-function devices specifically designed for petroleum distribution and industrial process industries. Some models allow automatic preset deliveries via mechanical valve and Weights and Measures approved ticket printing.

The 800 series register is the latest of four multi-function devices specifically designed for petroleum distribution and industrial process industries. Some models allow automatic preset deliveries via mechanical valve and Weights and Measures approved ticket printing.